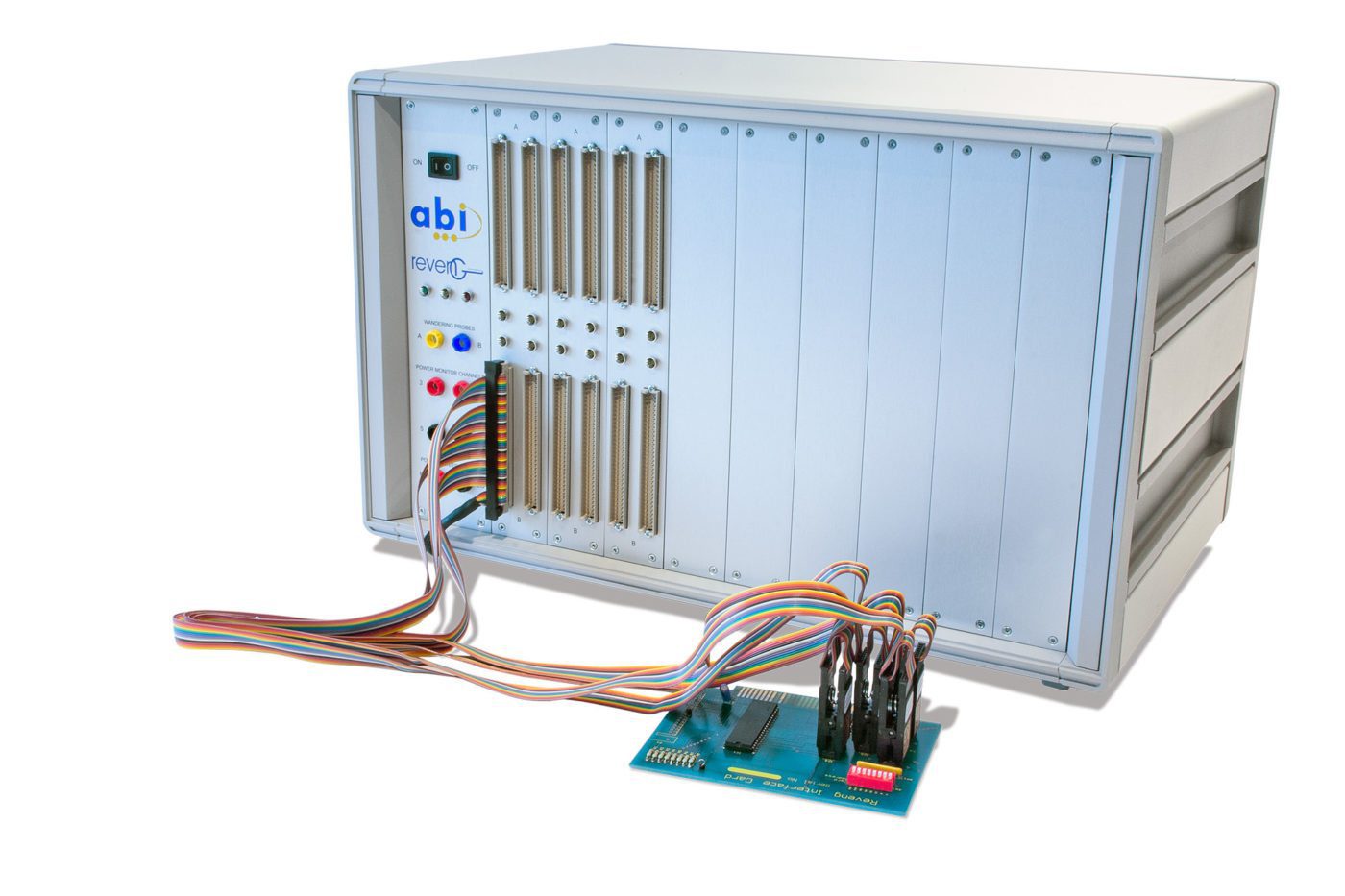

RevEng offers an effective method of creating professional quality circuit diagrams from a sample board. The RevEng system comprises a PC controlled continuity measuring hardware system, RevWin control software and EdWin, a fully featured CAD package. RevEng learns the connectivity of a sample circuit then produces a NetList (a list of the components and connections). The NetList is imported into EdWin to create professional quality circuit diagrams.

Overview

The learning process is achieved through clips, connectors and probes that are attached to clusters of components. RevWin guides the operator to place and walk the clips around the reference circuit. RevWin generates the most efficient sequence of clip combinations and movements to learn all possible connections. However, the operator can modify and override the automatic placement of the clips if necessary.

To minimise operator errors, the system applies an orientation check and pin check to confirm clip contact and position. RevEng learns without applying power to the board and limits the applied voltage and current so that semiconductor gates are not affected – it is also safe to use on low power technologies. There is a wide range of IC clips and connectors. If a clip or connector is not available or cannot be fitted due to the physical constraints of the board then the handheld probe and buzzer facilities are used.

Software Overview

The RevEng system comprises of 2 Software packages namely RevWin control software and EdWin, a fully featured CAD package.

RevEng is available in two configurations:

- Multilink Systems – Entry level system for low budget or small to medium circuits.

- Cabinet Systems – High pin count system for multiple requirements and large circuits. Cabinet equipped with control card and 1024 to 2048 channel measurement channels. Systems can be expanded to 2048 channels at any time after installation to meet changes in budget availability or application requirements.